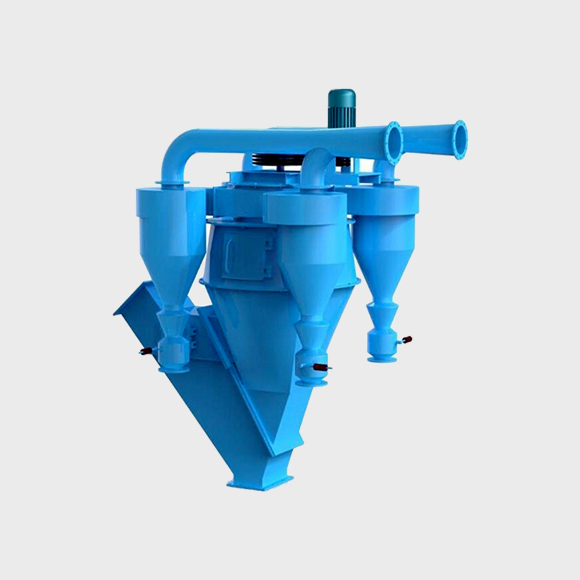

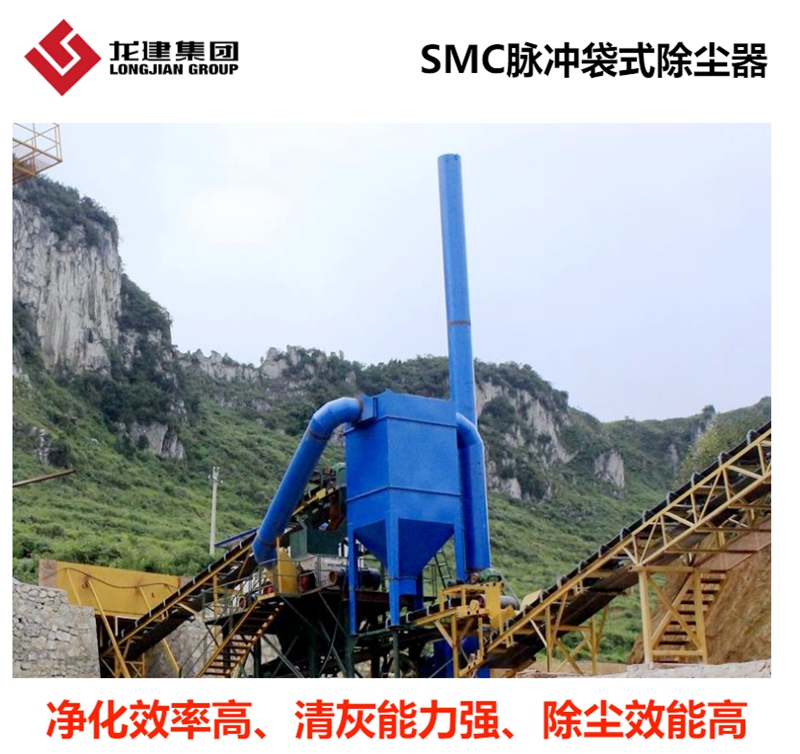

SMC pulse bag dust collector is a new type of high-efficiency dust collector improved on the basis of cloth bag dust collector. The improved pulse bag filter retains the advantages of high purification efficiency, large gas processing capacity, stable performance, easy operation, long filter bag life and small maintenance workload.

- Introduction

- parameters

This product is widely used by the company at home and abroad, and has been continuously improved. It has made great progress in the purification of dust-containing gas. Due to the advanced cleaning technology and the greatly improved gas-to-cloth ratio, it has large processing air volume, small footprint, and purification. High efficiency, reliable work, simple structure, small maintenance, etc. Dust removal efficiency can reach more than 99%. It is a mature, relatively complete and efficient dust removal equipment. When the dust-containing gas passes through the filter cloth, the gap between the fibers of the filter cloth or the gap between the dust adsorbed on the surface of the filter cloth separates the dust larger than the diameter of the gap, which is called screening. For the new filter cloth, due to the large gap between the fibers, this effect is not obvious, and the dust removal efficiency is also low. Only after a certain period of use, a certain thickness of dust layer is established on the surface of the filter bag, the screening effect is more significant. After cleaning, a certain amount of dust remains on the surface and inside of the filter bag, so it can still maintain a good dust removal efficiency. For the needle felt or pile filter cloth, because the felt or pile filter cloth itself constitutes a thick porous filter layer, it can fully play the screening effect, and does not rely entirely on the dust layer to maintain a high dust removal efficiency.

1. Comprehensive use of the advantages of sub-chamber back-blowing and pulse spray cleaning;

2. Overcome the shortcomings of insufficient strength of the sub-chamber backflushing;

3. Solved the characteristics of dust re-adsorption when pulse spray cleaning and filtration are performed simultaneously;

4. Adopt high-energy offline cleaning method, which has the advantages of large cleaning capacity, small system resistance, long filter bag life, high dust removal efficiency, etc.;

.jpg)